WELCOME

Welcome to Future Form, where we've built a reputation for trust and loyalty with our valued customers over the years.

Our commitment to quality is unwavering, as we leverage the latest technologies and high-quality materials to exceed industry standards.

ABOUT US

Future Form is situated in the Montague Gardens Industrial Area, Cape Town. Our 1200sq meter factory space houses state-of-the-art facilities that enable us to deliver premium products with precision and care.

For nearly three decades, our focus has been on producing quality products that meet or exceed customer expectations. We source materials only from ISO-certified suppliers, ensuring consistency and reliability in every aspect of our business.

Our export-driven model has successfully supplied products to European markets for many years, and we're proud of the relationships built with our international partners.

As a labour-intensive manufacturing company, we specialize in producing custom composite material or fiberglass products tailored to each customer's needs. From concept development to product design, prototype creation, and tooling preparation – we'll guide you through every step until your vision becomes reality.

State-of-the-Art Methods for Custom Composite Manufacturing

Various manufacturing processes are available to apply as technique in the shaping and making of products

.jpg)

CASTING

Casting of parts are done in preset tools with applicable materials for the required result

PATTERN AND TOOL MAKING

Pattern and tool making is a process of shaping a part to look like the original as master for the manufacturing of a casting tool

LASER AND WATER JET CUTTING

Water jet cutting and or laser preparation of parts are done through subcontractors to enhance quality and accuracy of certain products

HAND LAMINATIGN

Hand laminating is a process where materials are combined and controlled through hand manipulation

An individual worker will apply his/her skill to make a part in a preset tool with specific standards to follow

.jpg)

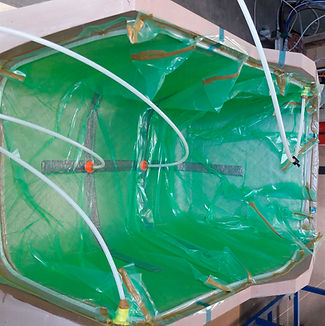

RESIN INFUSION

Infusion processes make use of vacuum processes to inject and saturate material to the correct level and is very reliable

VACUUM PROCESSES

Vacuum forming processes is a suitable method to form parts to exact standards